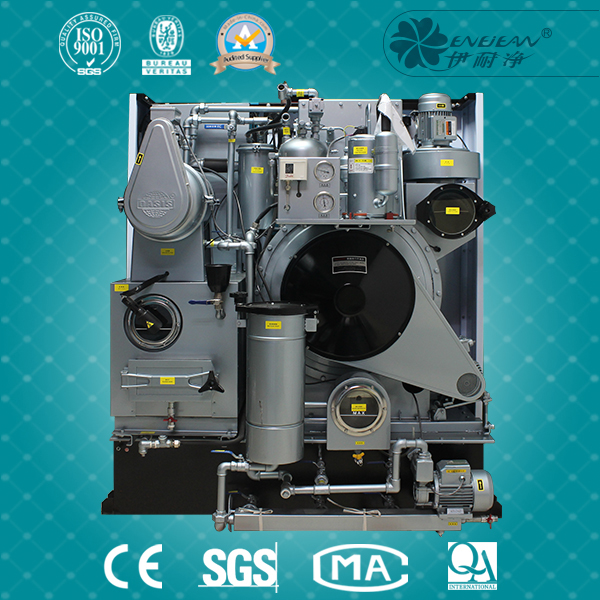

- Y300FSE3 Full closed dry cleaning machine

- Model Number:Y300FSE3

- Certification:CE,ISO9001

- Construction:stainless steel

- Function:dry cleaning

- Used for:Hotel ,Hospital, Laundry,school

- Packaging Details:wooden packing

- Delivery Detail:dilivery 7-25 days

- Inquire Online

The Chinese and English computer, can realize the Chinese manmachine dialogue, fault detection and automatic monitoring function, according to the experience of any write washing procedures, can realize the washing, dewatering and drying automatic control; automatic programmable operation.

Frequency conversion step less speed control, lower noise, more stable high dewatering. Has transferred automatically activated carbon adsorptionvrecovery kennel door, turn kennel door automatic pumping, the effective protection of the operator's health and the laundry room environment. Reducing clothing PCE gas residues, environmental protection and energy saving.

Germany's Siemens power,European style design, compact structure, full closed refrigeration recovery system, a computer board, refrigeration recovery system, all kinds of pneumatic components valve, electromagnetic valve, lowvoltage electrical appliances, bearings, seals and other all use well-known brands at home and abroad, the performance is more stable and reliable. Spindle adopts advanced technology of the maintenance free, lifetime without refueling and maintenance.

The unique and advanced refrigeration recovery system, environmental protection and economy in one of the sets, not only effectively improves the solvent recovery, and ensure the environmental protection, health.

Inside and outside the cage, air duct system, button collector, liquid water separator and distillation cooling tower, distillation and other key components are high quality stainless steel structure, large caliber loading door, fetching clothes more conveniently, the rotor cage by punching technology unique, mesh than similar products, the 1GR18NI9TI stainless steel, wear the rate of small no injuries clothes, high cleanliness.

The three cylinder double filter structure, nylon centrifugal filter device, filter systems using super filtration system of Japanese cherry blossom, strong adsorption capacity, good effect, the average 25-30 washing machine recovery distillation time, light colored clothing can be washed, compared with other similar products by distillation for several times, complete distillation, the four dirty liquid of vinyl chloride fully recovered, dirty sewage discharged after distillation in the dry state, saving water and electricity 50%, high heat energy utilization rate, the best price performance machine.

The automatic washing function with solvent and solvent box mirror box. Without manual dis-assembly and cleaning, saving time and labor, to prevent the four vinyl chloride leak effectively, protect the environment and the health of operators.

Button collector, fuzz collector adopts unique toughened glass cover, does not need to be opened to check. In appearance, safety, environmental protection, the use of strong.

|

Item |

Y300FSE10 |

|

Water Capacity |

10 to 12kg |

|

Washing Cylinder |

690×440mm |

|

Capacity/Load Ratio |

20 |

|

Washing Speed |

40RPM |

|

Spinning Speed |

400RPM |

|

No.1 Oil Cylinder Capacity |

80 |

|

No.2 Oil Cylinder Capacity |

80 |

|

No.3 Oil Cylinder Capacity |

110 |

|

Distillation Tank Capacity |

130 |

|

Nylon Filter Capacity |

25 |

|

Power of Washing Motor |

0.4 |

|

Power of Spinning Motor |

1.5 |

|

Power of Pump |

0.55 |

|

Power of Air Blower |

0.75 |

|

Power of Nylon Filter Motor |

0.37 |

|

Power of Drying Heater |

6 |

|

Distillation Power |

5.4/7.2 |

|

Power of Compressor |

1.5 |

|

Noise |

70 |

|

Weight of Whole Machine |

1000 kg |

|

Weight of Packing Case |

100 kg |

|

Power Supply |

AC220V/380V/50Hz |

|

Installed Capacity |

16.5/5.2 KW |

|

Pressure of Inlet Water |

0.2-0.4 mpa |

|

Pressure of Compressed Capacity |

0.4-0.6 mpa |

|

Steam Pressure |

0.4-0.5 mpa |

|

power Consumption |

6/2 KW/h |

|

Water Consumption |

300 L/h |

|

Steam Consumption |

25 kg/h |

|

Contour Dimension |

1550×1180×2000mm |

|

Contour Dimension of Package |

1670×1250×2120mm |

|

Power Input Wire |

6/4 mm² |

|

Compressed Air Inlet |

ф8 mm |

|

Water outlet |

G1/2 in. |

|

Water Inlet |

G1/2 in. |

|

External Steam Inlet |

G1/2 in. |

|

External Steam Outlet |

G1/2 in. |